BIMR Facilities

The Brockhouse Institute has historically created, developed, and supported a number or research facilities at McMaster that have become successful independent entities. The most recent of these partner facilities to have become independent is the Canadian Centre for Electron Microscopy (CCEM). Support of these facilities remains a priority for the institute, and we will work toward expanding their user base, developing additional capabilities, and supporting collaborative work using the available infrastructure, both internally and with external partners.

The institute currently houses and operates several facilities that help support materials research, infrastructure, and operations at McMaster. These include the Thermal Analysis Facility, the Cryogenics Facility, and the Centre for Crystal Growth.

Thermal Analysis Facility

The behaviour of materials at high temperatures is critically important to their potential applications. The tempartures at which thermal phase transitions occur can guide the use of particular materials within products that range from coffee cups to heat shields in the aerospace industry. Our thermal analysis facility houses state-of-the-art thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) equipment capable of determining decomposition temperatures of polymers, metals, and alloys, as well as phase transitions in plastics and numerous composites. This facility houses a Netzsch 449 F3 Jupiter HV-STA system equipped with two furnaces, capable of TGA-DTA-DSC measurements in the -150-1600°C temperature range and a range of different atmospheres. This instrument also has the ability to accurately measure specific heat capacity of a wide range of materials.

The behaviour of materials at high temperatures is critically important to their potential applications. The tempartures at which thermal phase transitions occur can guide the use of particular materials within products that range from coffee cups to heat shields in the aerospace industry. Our thermal analysis facility houses state-of-the-art thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) equipment capable of determining decomposition temperatures of polymers, metals, and alloys, as well as phase transitions in plastics and numerous composites. This facility houses a Netzsch 449 F3 Jupiter HV-STA system equipped with two furnaces, capable of TGA-DTA-DSC measurements in the -150-1600°C temperature range and a range of different atmospheres. This instrument also has the ability to accurately measure specific heat capacity of a wide range of materials.

Cryogenics Facility

The electronic and magnetic properties of materials are often key to their characterization and application. The electronic/magnetic characterization facility operates a Quantum Design SQUID magnetometer with capability of measurements between 1.8 and 800K and magnetic fields up to 5T. It also operates a Quantum Design PPMS and Oxford Instruments Maglab system with capabilities for measuring AC susceptibility, specific heat and electrical transport between 1.5K and 400K in magnetic fields up to 9T. In addition, facility also operates a He liquefier for the Institute, which provides the required liquid He to the SQUID systems as well as nuclear magnetic resonance (NMR) equipment in individual labs and the McMaster NMR Facility.

The electronic and magnetic properties of materials are often key to their characterization and application. The electronic/magnetic characterization facility operates a Quantum Design SQUID magnetometer with capability of measurements between 1.8 and 800K and magnetic fields up to 5T. It also operates a Quantum Design PPMS and Oxford Instruments Maglab system with capabilities for measuring AC susceptibility, specific heat and electrical transport between 1.5K and 400K in magnetic fields up to 9T. In addition, facility also operates a He liquefier for the Institute, which provides the required liquid He to the SQUID systems as well as nuclear magnetic resonance (NMR) equipment in individual labs and the McMaster NMR Facility.

Centre for Crystal Growth (CCG)

The BIMR is home to Canada’s most extensive suite of infrastructure dedicated to the crystal growth of new and existing materials, the Centre for Crystal Growth (CCG). The CCG houses several large crystal growth furnaces that are optimized for the growth of different types of crystals. However, crucial to the success of the CCG is the fact that supporting sample preparation and characterization infrastructure is also present, where it is used to prepare the starting materials required for crystal growth, to anneal or post-anneal materials at intermediate stages in the crystal growth process, and characterization infrastructure which allows the crystal grower to assess which phases of crystalline materials are being produced, and what the nature of the impurities are in the growth process. A successful program of crystal growth is a multistep process that alternates between sample preparation, sample characterization, and single crystal growth and iterates on itself until the desired large and pristine single crystal of a new material is achieved.

The BIMR is home to Canada’s most extensive suite of infrastructure dedicated to the crystal growth of new and existing materials, the Centre for Crystal Growth (CCG). The CCG houses several large crystal growth furnaces that are optimized for the growth of different types of crystals. However, crucial to the success of the CCG is the fact that supporting sample preparation and characterization infrastructure is also present, where it is used to prepare the starting materials required for crystal growth, to anneal or post-anneal materials at intermediate stages in the crystal growth process, and characterization infrastructure which allows the crystal grower to assess which phases of crystalline materials are being produced, and what the nature of the impurities are in the growth process. A successful program of crystal growth is a multistep process that alternates between sample preparation, sample characterization, and single crystal growth and iterates on itself until the desired large and pristine single crystal of a new material is achieved.

Partner Facilities

Information Box Group

Canadian Centre for Electron Microscopy Learn More

CCEM is a world leading, state-of-the-art facility dedicated to providing a full suite of electron microscopy equipment, facilities, and expertise. This world-class facility has capabilities that are unmatched in Canada, and continues to expand and push the frontiers of electron microscopy.

Centre for Emerging Device Technologies Learn More

The CEDT facilitates the study of optical, electrical, mechanical, and biological properties of semiconductors and related materials and promotes the development of technology based on these materials.

Biointerfaces Institute (BI) Learn More

BI is a state-of-the-art facility implementing high-throughput research pipelines to investigate the nature of the biological/material interface, or biointerface. This institute houses an extensive array of instruments geared toward characterization of biomolecules and materials.

McMaster Manufacturing Research Institute Learn More

MIRI is focused on finding solutions to the challenges faced by today’s manufacturing industry and optimizing every facet of the machining process.

The McMaster Automotive Resource Centre (MARC) Learn More

MARC is one of Canada’s leading research facilities in electric and hybrid vehicles where researchers, students and industry professionals are working to resolve the issues facing the automotive industry. Together, these teams of engineers, scientists, social scientists and their students are developing sustainable solutions for the industry including the development of hybrid and electric powertrains, building highly efficient and cost-effective powertrain components and identifying light materials to make cars more fuel efficient.

McMaster Analytical X-ray Diffraction Facility (MAX) Learn More

The MAX is a service, research, and teaching laboratory operated by the Faculty of Science and located within the Department of Chemistry and Chemical Biology. It supports Science and Engineering research at McMaster University, as well as train students in the theory and practice of X-ray diffraction. This facility also provides fee for service characterization of chemicals and materials for external clients from industry and from other universities.

Photonics Research Laboratory (PRL) Learn More

The Photonics Research Laboratory at McMaster University is a laser facility that is aimed at providing an interdisciplinary environment for physics, chemistry, materials science, electrical and mechanical engineering. The facility has a number of pulsed laser systems covering nanosecond to femtosecond regimes as well as corresponding time-domain optical detection instruments. The laser systems can be used in pulsed laser machining, additive manufacturing, material property characterization (e.g., through LIBS), and surface modification applications. The facility also has several custom-built optical imaging instruments including superresolution (STED), confocal, multiphoton, hyperspectral and fluorescence lifetime imaging.

The Nuclear Magnetic Resonance (NMR) Learn More

The NMR Facility was established in 1985, with funding from NSERC and McMaster University. This Facility currently maintains 8 NMR spectrometers including a Bruker AVANCE III 700MHz, funded by CFI and the Province of Ontario. The Facility is highly regarded in the Canadian chemical community for its versatility in the types of samples (organic, inorganic, biochemical, geological, industrial, forestry, agricultural and biomedical materials) that can be analyzed. It’s also known for the number of nuclei that can be studied by solution and solid state NMR.

The McMaster Nuclear Reactor (MNR) Learn More

MNR first became operational in 1959 and was the first university-based research reactor in the British Commonwealth. Originally designed to operate at a maximum power of 1 MW, MNR was upgraded during the 1970s to its current rating of 5 MW with a maximum thermal neutron flux of 1 x 1014 neutrons/cm2s. MNR is classified as a medium flux reactor and it is by far the most powerful research reactor at a Canadian university – the handful of so-called “Slowpoke” reactors at other institutions typically operate at a power of 0.02 MW. This facility will also house the McMaster Small Angle Neutron Scattering (MacSANS) facility, which will enable the study of materials at the atomic level.

The Centre of Excellence in Protective Equipment and Materials (CEPEM) Learn More

CEPEM assists research and development needs for Canadian companies, both existing and new, so that they can meet today’s needs for Canada but also develop the next generation of personal protective equipment (PPE) to become global leaders in the future.

Meeting Rooms

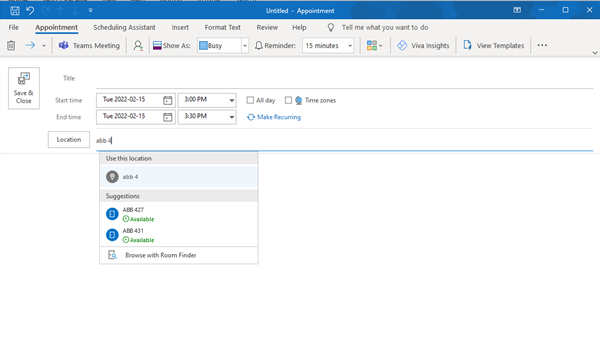

We are pleased to announce that the BIMR Board Room (ABB 427) and the classroom (ABB 431) have been added as bookable assets in your Outlook calendar (this pertains to McMaster BIMR members only). This means that when you book a meeting, you can now add ABB 427 or ABB 431 as locations, and Outlook will automatically check if these rooms are available for booking.

ABB 427 is a small boardroom. It can fit up to 8 people. You can share your presentation on the TV screen. This room is ideal for small group meetings or one-on-one meetings with students or partners.

Be inspired by the work of colleagues with the journals covers exhibited on the wall, showcasing the research of our BIMR members. And if you want to add a cover of your own research, please feel free to reach out to us to be added to the collection!

ABB 431 is also called the Seminar room. It is a classroom that can accommodate up to 16 attendees plus the presenter. Use the board or a projector for your presentation. It is ideal for small lectures or larger groups.

Note: If you require a projector when using ABB 431, please email bimr@mcmaster.ca to book it.

How to book the ABB 427 and ABB 431 rooms using Outlook:

If you would like to book a meeting in either of these rooms using your own calendar, please make sure you include them in the “Search for a room or location” field in Outlook (see example below). For those using Mac OS, this feature also works in the Apple Calendar app (“add location” field), as long as you are using Microsoft Exchange for your email and calendar. Outlook will automatically check if these rooms are available for booking.

If available, you will see a green checkmark icon, and the room will show up as “booked” at the time you selected. To view all the bookings for these rooms, you can use the “Add calendar” button and select “Add from directory”, then search for ABB 427 or ABB 431; this results in a new calendar being added that shows when these rooms are available or booked.

A few rules:

Please do not change someone else’s booking.

Please do not double book. If you see that the rooms are already booked, please choose an alternative time frame for yourself.

If there is any issue please send an email to bimr@mcmaster.ca.

Thank you all for your cooperation.